The diameter of two alternate bent up bars is given as 10 mm center to center. The thickness of the waist slab is given as 125 mm. The width of both landing is given as 1000 mm and the width of beams provided on both landing is 250 mm. Hypotenuse is calculated as 292 mm through Pythagoras theorem. The cross section of the staircase contains the following dimensions:. The width of landing 2 is also taken as 2500 mm The width of landing 2 is also taken as 1000 mm The width of the waist slab is taken as 1200 mm The length of the waist slab is taken as 2500 mm

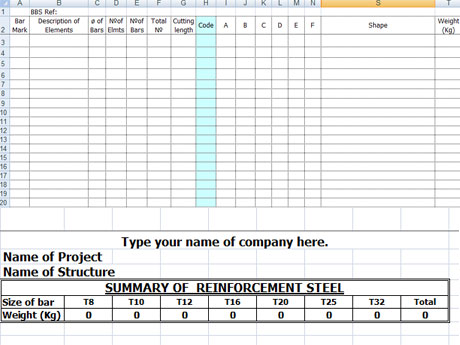

The length of landing 1 is taken as 2500 mm The width of landing 1 is taken as 1000 mm There are also two waist slabs but here one waist slab is considered for the calculation purpose. This allows an easy way to check whether things are delivered as per requirement.In the example provided in the video, there are two landings as landing 1 and landing 2. The delivery note provides a summary of entire rebar delivered to a particular site. This makes sure a good communication between various stakeholders such as people from production, delivery to site, and installation site. The bar tags are quite obvious and simple to read. That's why it provides full control on the sorted bar list. Sorting and personalization is performed according to user-defined order. Due to this, it's very easy to point out the optimized cut lengths and how each length can be bent. The personalized sheet can display bar lengths to be cut, and the bar marks. These aspects make the cutting a reasonable affair. Personalization is done using very complex algorithm to make sure that minimum waste and off cuts are achieved. It allows you to also change the weight limitations for grouping rebar and putting individual tags.

It also permits an user to modify the length of bar stock to reflect the currently availability in stock. A user can choose to arrange by material's diameter/length/bar mark or by material's weight/length or by any other order. Arranging and personalization are performed based on four user defined levels of priority.

0 kommentar(er)

0 kommentar(er)